Dishwasher Parts

At Triangle Rubber and Plastics, we work with every elastomeric material available and can meet your dishwasher parts molding specifications with our two decades of plastic and rubber molding experience. Not only is experience an irreplaceable asset in our industry, but within that time, our team has earned a reputation for excellence in this sector of the consumer appliance industry. Triangle Rubber and Plastics continues to build upon our success, looking towards the future as we expand our molding capabilities and exceed our customers’ expectations.

Grommet/Seal Molder

Over the past decade, Triangle Rubber & Plastics has invested our time in becoming one of the industry’s most accomplished grommet seal molders. Our precision molding methods are perfect for any Grommet/seal molding project, ensuring that these vital pieces of equipment between the pump and the sump will function according to customer designs. manufactures over 3.5 million of these grommet seals each year.

Vertical Integration for Molding Plastic Dishwasher Parts

Because this molded dishwasher part is a unique component involving two plastic rings over-molded with rubber, Triangle Rubber uses a vertical integration process to produce this part. Vertical integration consists of molding plastic rings at the thermoplastic division before sending them to our rubber division to be over-molded with rubber materials. That’s the advantage of working with a plastic and rubber molder–we can do both, in-house.

Check Valve Molder

Another over-molded plastic part that we commonly supply for dishwashers is the check valve. This process similarly involves a plastic insert from the plastic division and a silicone seal that our rubber division overmolds onto the plastic. The strategic direction of Triangle Rubber & Plastics is to provide high-quality elastomeric and plastic material for every project, ensuring that every molded dishwasher part is an example of the high quality that our company is known for.

Vibration Isolator Molder

We supply several types of vibration isolators, all produced according to our customers’ specifications. Because most vibration isolators are used between the pump motor and the frame to reduce any noise from the motor, we understand that these projects must be manufactured with high levels of precision.

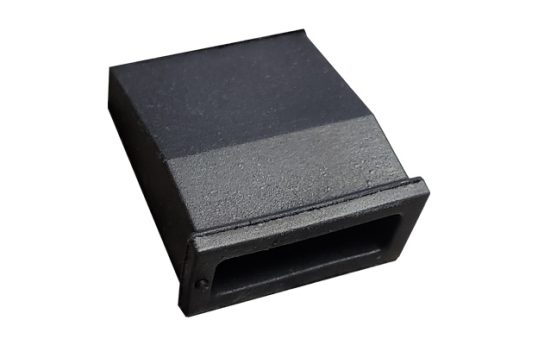

Custom Plastic Components

The parts above are just a small sample of what we can do. Triangle Rubber can mold a wide range of components according to customer designs, including everything from internal plastic brackets to soap dispenser bins and lids. Just tell us what you need, and we’ll work with you to determine your needs and mold the right product for you.