Rubber Molding

Triangle Rubber & Plastics is one of the leading suppliers of expert molded rubber products for a wide range of industries. Our rubber molding division covers over 90,000 square feet of molding equipment, compounding processes, and a laboratory. We’re also well-versed in developing unique automation technology designed to assist in unloading and directing finished products to the next step of production, improving the efficiency of our rubber molding processes. We design and develop this equipment as needed for specific projects, finding innovative ways to reduce lead times for our customers.

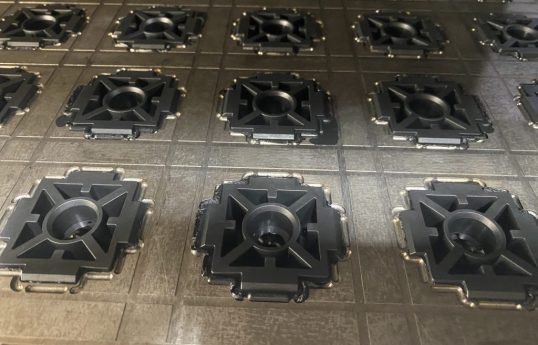

Compression Rubber Molding

At Triangle Rubber, we are flexible in our compression molding capabilities, using a variety of equipment ranging from 200 to 500 ton to create custom components for our customers, bringing their designs to life.

Transfer Rubber Molding

Transfer rubber molding is an excellent manufacturing technique for producing large numbers of parts, being able to process more parts per cycle with less load time than compression molding. This is also the go-to method for designs that require rubber molding over plastic or metal inserts. Our transfer rubber molding equipment ranges from 200 to 500 tons, and can accommodate virtually any type of elastomeric material available, from natural rubber to silicone.

Injection Rubber Molding

In addition to compression and transfer molding, Triangle Rubber also maintains several injection molding presses ranging from 350 to 500 tons. With this equipment, we can quickly produce large and thin-walled hollow rubber products, especially ones whose design doesn’t lend well to other molding techniques.

Rubber Insert Overmolding

One of the major benefits that our partners gain from working with us is our in-house rubber over-molding capabilities. Triangle Rubber is vertically integrated–not only do we offer over-molding services, but we can also mold plastic inserts at our plastic division and then send them to our rubber division to be over-molded.

Rubber Molding Materials

Triangle Rubber & Plastics maintains an exemplary in-house laboratory that can formulate unique rubber compounds that meet the specifications required by its applications. Learn more about this capability here.

- Rubber Materials

- Thermoplastic Elastomers

- Silicone Rubber

Exceptional Customer Service

Triangle Rubber & Plastics is dedicated to providing exceptional customer service to our partners on every project. We prioritize communication to ensure that they are informed throughout the process and that we are meeting or exceeding their expectations.