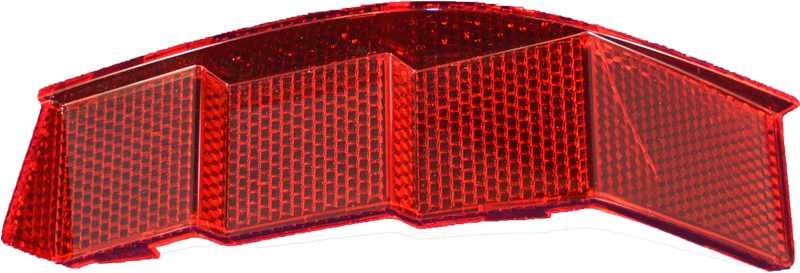

Reflex Lenses

Triangle Rubber & Plastics maintains high-quality standards for the production of elastomeric and plastic-molded products, including reflex lenses. Our reputation for excellence has earned our company countless loyal customers from the world-wide market and has only gained prominence throughout our decades of plastic molding experience.

Accommodating Your Reflex Lens Needs

Reflex lenses are one of many molded lens styles we can supply to automotive customers. Our lens molding capabilities can accommodate both Polycarbonate and Acrylic lens types, and we can custom mold a variety of lens orders, whether you require clear, amber, or red material. At Triangle Rubber & Plastics, we take our customers’ material-grade specifications and bring reflex lenses to life. If you have any questions regarding which materials are best suited for your projects, our team can assist you with material recommendations.

One-Stop Reflex Lens Mold Shop

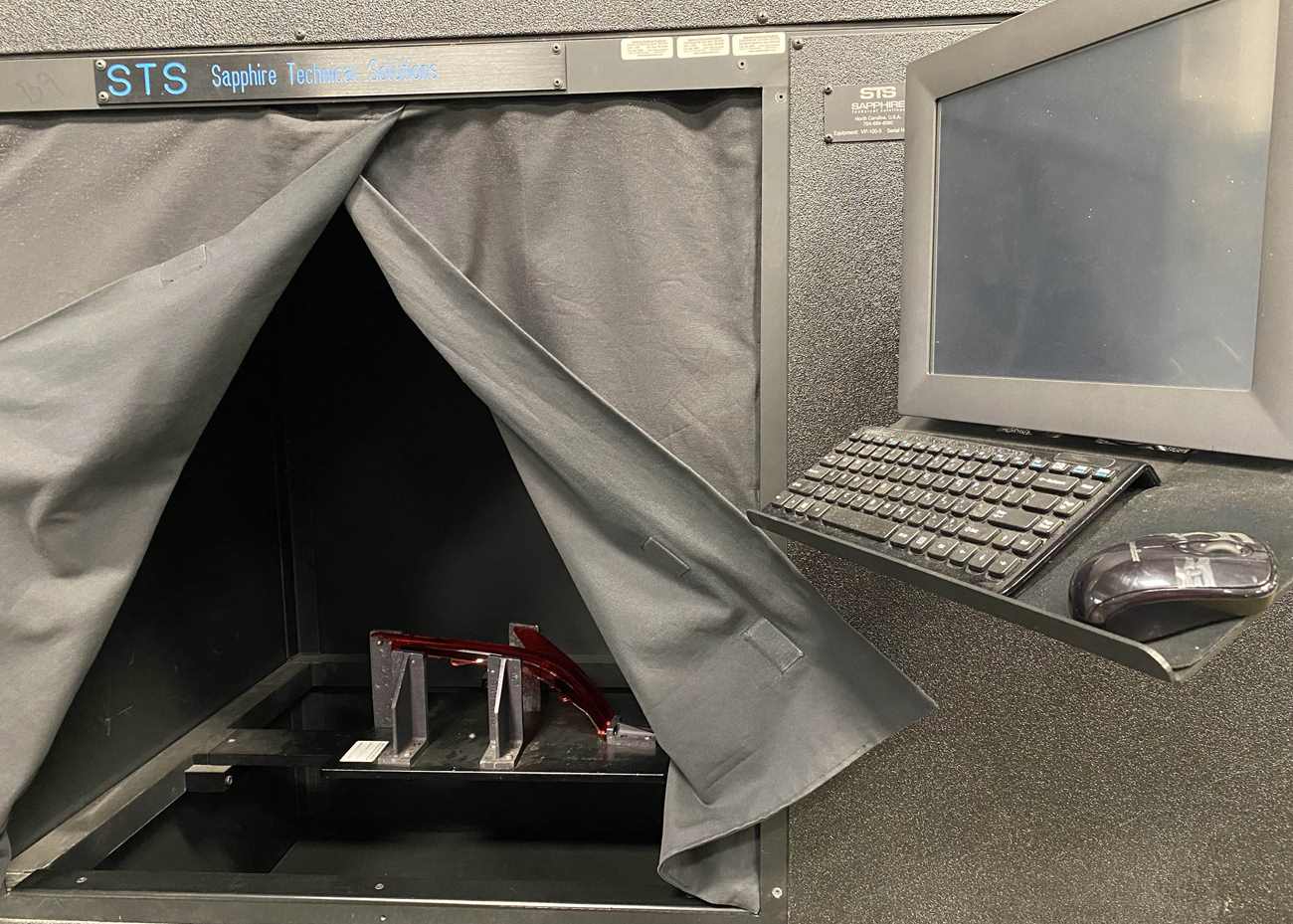

Vertical Photometer for Reflex Lens Molding

Triangle Rubber & Plastics is a company that is fully equipped in all areas of reflex lens molding, and as such, we have invested in vertical photometer machinery. Vertical photometers are used to measure the amount of light that is reflected back from the lens. With our in-house photometer, we can evaluate the performance of our lenses before they are sent out to our customers. This allows our engineering team to easily define the production process that will yield a lens within the customer’s tolerance while not depending on a third party for testing. We also use the photometer during production runs to monitor the reflex and ensure that the process continues to produce high-quality parts.

Molders without a photometer risk molding large quantities of faulty parts, not knowing about flaws until their customers evaluate them. Triangle Rubber & Plastics avoids this risk and uses our equipment to ensure excellence in every order.

Top Reflex Lens Molder

Triangle Rubber & Plastics can meet the rigorous specifications required for reflex lens orders by utilizing the latest technologies to meet your specific needs. It is important to partner with a molding company that understands the intricacies of complex molding and automotive design, which is why our company prides itself on being a dependable and flexible supplier.

Beyond our assortment of high-quality molding materials and innovative technology, Triangle Rubber & Plastics stands out in our industry due to our talented and committed workforce. Our molding team is composed of hard-working, customer-oriented employees, each boasting years of their own experience in the industry. We benefit from the creative energy and participation of our employees in meeting customer quality goals, expectations, and needs. If you find yourself with inquiries regarding your order, our experienced staff can help you select the best process for your application.

IATF Registered for Reflex Lens Molding

Triangle Rubber & Plastics is IATF-registered as a supplier of reflex lenses and other molded products for the automotive industry. This certification further marks our company as a trustworthy molding supplier, in addition to our global reputation for precision and efficiency.