Refrigeration

Triangle Rubber & Plastics offers expert plastic and rubber molding services to meet the needs of our partners in refrigeration equipment manufacturing and the production of consumer refrigeration appliances. We work closely with each of our customers to ensure that we produce high-quality and long-lasting components.

Rubber Motor Isolators

Like any motor, refrigeration motors require rubber isolators for noise control and quiet operation, especially equipment for consumer applications. Triangle Rubber has decades of experience at your service molding rubber motor isolators as well as related rubber components for refrigeration units. We utilize the latest technology to provide you with motor isolators that meet industry standards and remain durable throughout their life cycle.

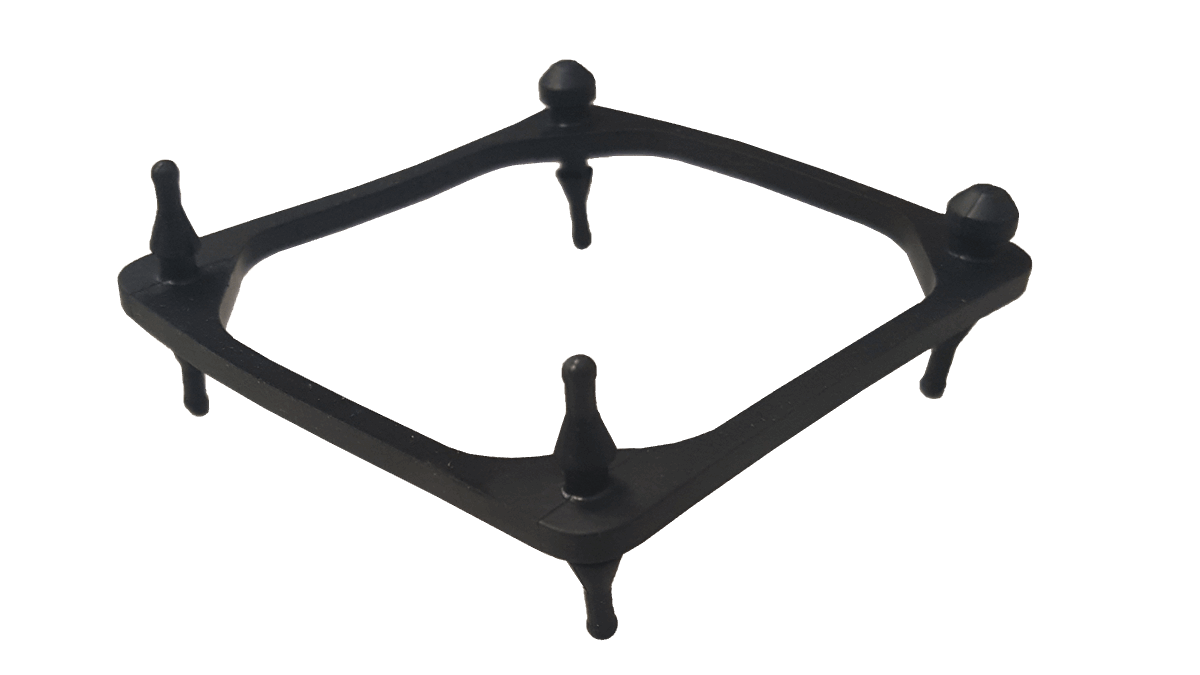

Rubber Fan Isolators

Another rubber part that we regularly supply for refrigeration equipment and applications is rubber fan isolators. These work similarly to motor isolators, providing noise control during the unit’s operation. Triangle Rubber has been molding these rubber parts for decades and ensures that each product is made according to our customers’ precise standards.

Plastic Components

Rubber molding isn’t the only service we offer our partners in refrigeration manufacturing. We also have everything you need for molding a wide range of plastic components, including but not limited to doors, shelves, drawer slides, ice buckets, and handles. We are familiar with the needs of the consumer appliance market, understanding that these plastic parts serve both functional and aesthetic purposes, and we take care to mold your components to meet the standards for both. Our plastic components will withstand the temperatures common in refrigeration units, as well as the everyday wear and tear that consumer appliances experience when in use.

Choose an expert plastic and rubber molding supplier

Triangle Rubber & Plastics has over seven decades of experience in rubber and plastic injection molding. We’ve watched the industry grow and change, and we’ve grown and adapted with it. Take advantage of our industry experience and extensive knowledge of plastic injection molding and rubber molding to get the best possible components for your equipment.