Laundry

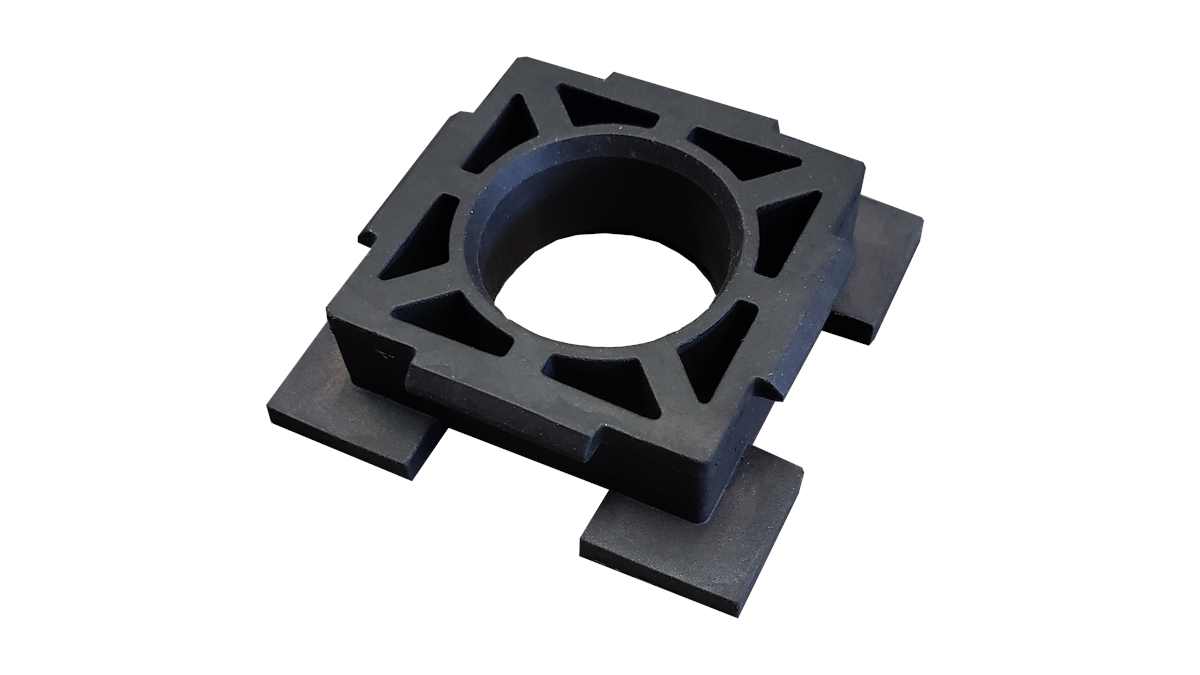

Triangle Rubber & Plastics offers our experience to laundry equipment and appliances manufacturers, supplying quality rubber and plastic molded components that meet quality and industry standards. From molded roller ties to cosmetic face plates, we have decades of molding experience to offer this sector of consumer appliances.

A Case Study of Vertical Integration

Triangle Rubber & Plastics also offers vertical integration to fully assemble a wide range of over-molded products, such as roller tires for laundry equipment. First, the roller tire is molded by our rubber division as usual. Once that step is complete, the parts are sent to our thermoplastic facility where the part is placed into a plastic injection mold and a plastic hub is over-molded onto the rubber. Then, we finish the assembly by installing the metal bushing into the plastic hub.

Because Triangle Rubber is vertically integrated, we can offer plastic over-molded tires with much more efficiency and improved quality, providing a fully assembled product to our customers under one roof.