Refrigerator Parts Molder

At Triangle Rubber & Plastics, we create the plastic or rubber components needed for your consumer appliances, including Refrigerator parts. Does your business require custom molded parts? If you are an appliance manufacturer who has been looking for a dependable company that can offer rubber molding, single-shot injection molding, and two-shot molding services for refrigerator parts, then your search is over! Contact our team and let us take care of all your molding challenges.

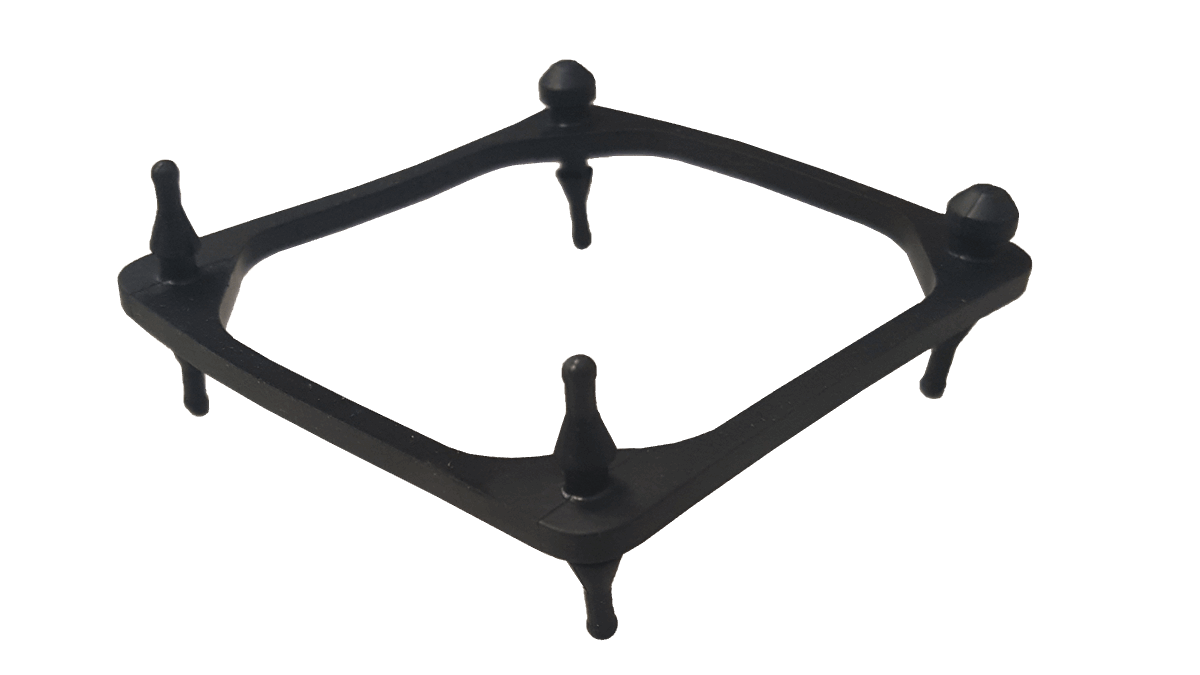

Refrigerator Parts Molder: Rubber Motor Isolators

Drawing upon years of experience, Triangle Rubber & Plastics produces molds for rubber motor isolators, among other refrigerator parts. These types of projects utilize our cutting-edge technology, producing rubber motor isolators that will be used for noise control according to our customers’ designs.

Quality Refrigerator Parts Made Possible with Triangle Molding

At Triangle Rubber & Plastics, we understand that our customers design refrigerator parts intended for enduring use. Our refrigerator parts molding abilities can easily meet the needs of our customers’ designs. Moreover, since the molding process is often collaborative, we prioritize making each project an enjoyable and productive experience for the customers who come to us for their molded refrigerator parts projects.

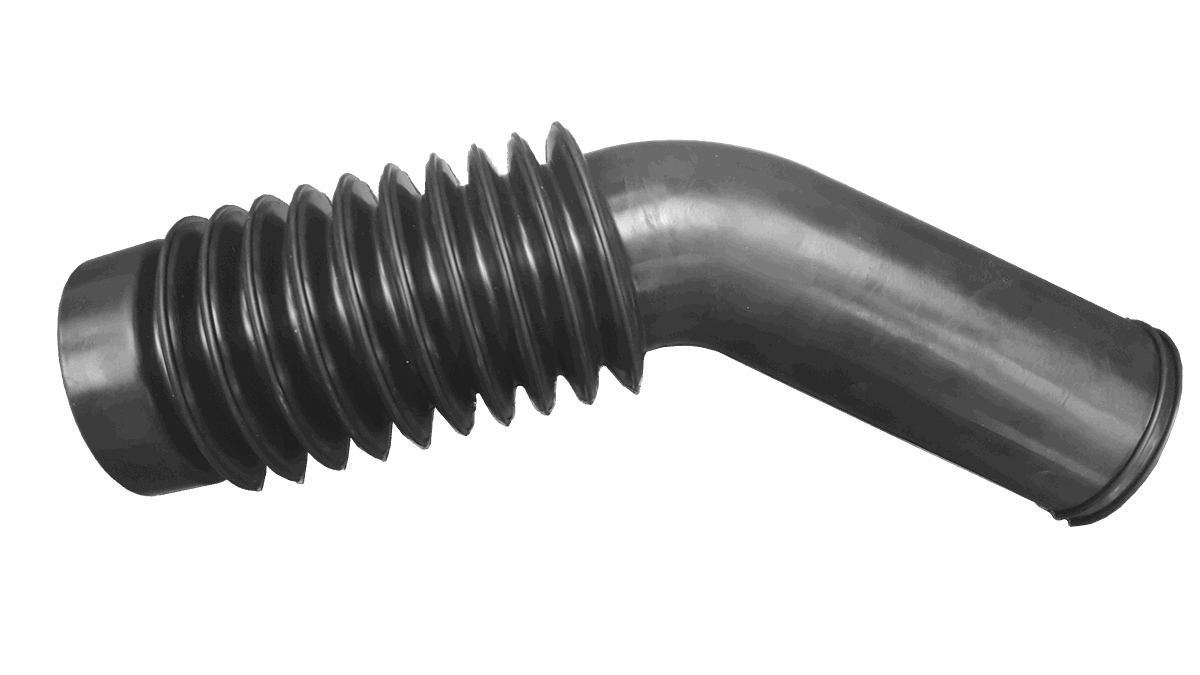

Refrigerator Parts Molder: Rubber Fan Isolators

In the same way that Triangle Rubber & Plastics can produce rubber motor isolator refrigerator molds for noise control, we can also supply our customers with custom rubber fan isolators for noise control as well. As is the case for all of the refrigerator parts we mold, the rubber fan isolator projects we work on receive the highest quality service. We ensure that your products are molded to your precise specifications, eliminating the risk of defects for our customers. With years of experience under our belt, Triangle Rubber & Plastic meets every molding need with excellence.

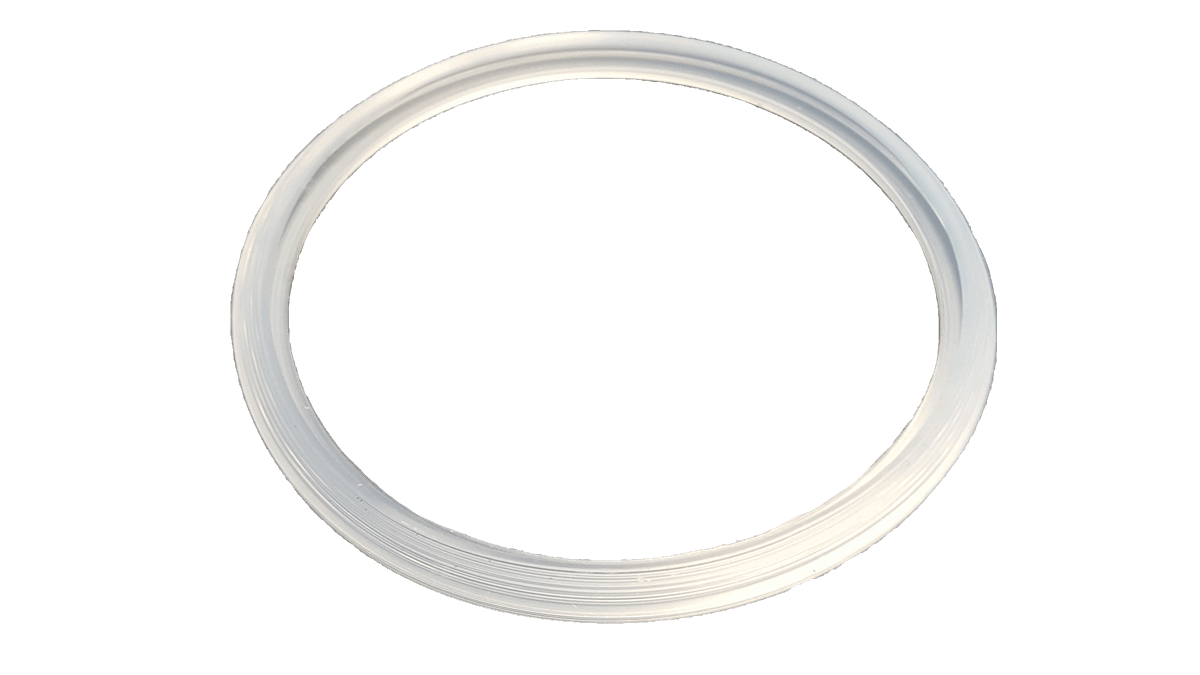

Refrigerator Parts Molder: Plastic Components

Triangle Rubber & Plastics has worked on countless plastic components projects for refrigerator parts molding, from plastic doors, shelves, and drawer slides to ice buckets and handles. These plastic components not only serve practical purposes but also must satisfy the needs for highly aesthetic parts, given that these refrigerator molded parts are designed to be seen by the end user. Consequently, these types of projects require a plastic molding service provider with advanced abilities to meet customers’ specifications for both functional and decorative needs.