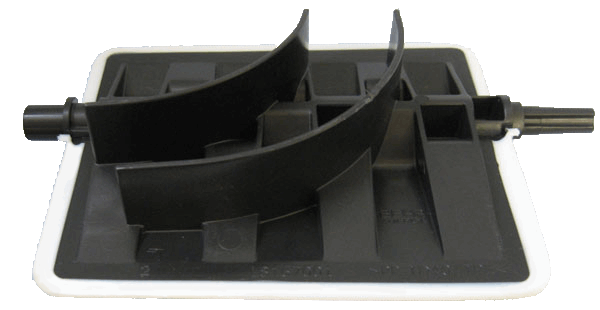

HVAC Diverters

Diverters play an essential role in HVAC assemblies, redirecting airflow for optimal vehicle heating and cooling. These plastic parts can often be complicated to make, with their irregular geometries and many surface features, but we’ve got you covered. Triangle Rubber & Plastics is more than capable of producing your HVAC diverters.

Accommodating HVAC Diverter Projects of Every Size

Diverters are important for ensuring your customers’ satisfaction. They ensure driving comfort and proper vehicle circulation, allowing the HVAC system to maintain a comfortable interior environment for the driver and passengers.

Triangle Rubber is here to provide you with quality diverters made to your specifications. Over the years, we have made nearly every type of plastic diverter and offer our experience in molding across a wide range of sizes, shapes, materials, and production volumes.

Expert two-shot plastic molding for diverters

Two-shot molding is one of the main capabilities we offer for diverter production. The initial shot produces a structure molded with a hard material such as polypropylene during this process. The second shot involves a soft TPE material that seals the diverter to its housing, protecting it from environmental conditions. With our expertise and equipment, we produce diverters with consistent seals, preventing air leakage and offering superior mechanical operation.

We maintain two-shot plastic molding equipment ranging from 200 to 1200 ton, operated by a highly experienced workforce to ensure that our customers receive the best possible quality for their products.

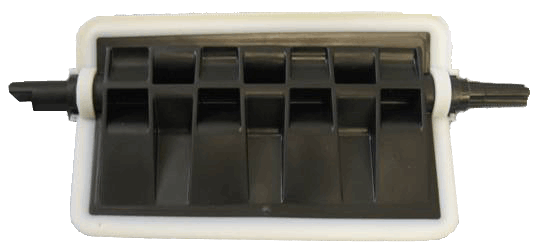

Versatile Single-Shot Plastic Molding

Sometimes, certain HVAC diverter designs just are not feasible to manufacture using the two-shot plastic molding process. Triangle Rubber offers single-shot plastic molding for these designs to produce durable and high-performing components. In addition, we install a foam seal around the outer edge of the diverter once molding is complete, which functions much like the second shot described above, sealing in air and providing excellent mechanical operation.

Our facilities house machines ranging from 100 to 1000 ton, allowing us to offer our customers a wide range of versatility in plastic molding.