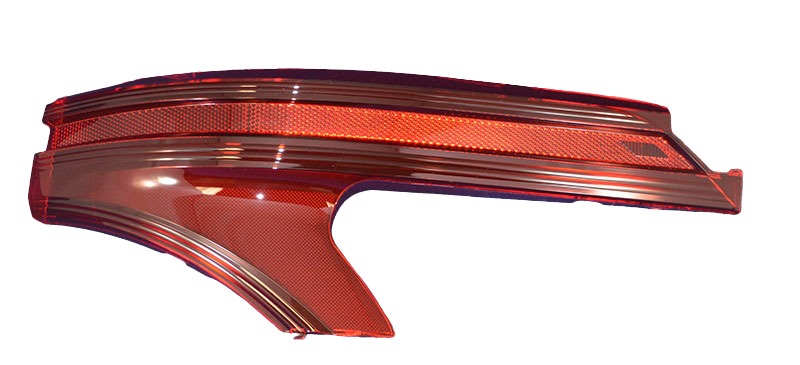

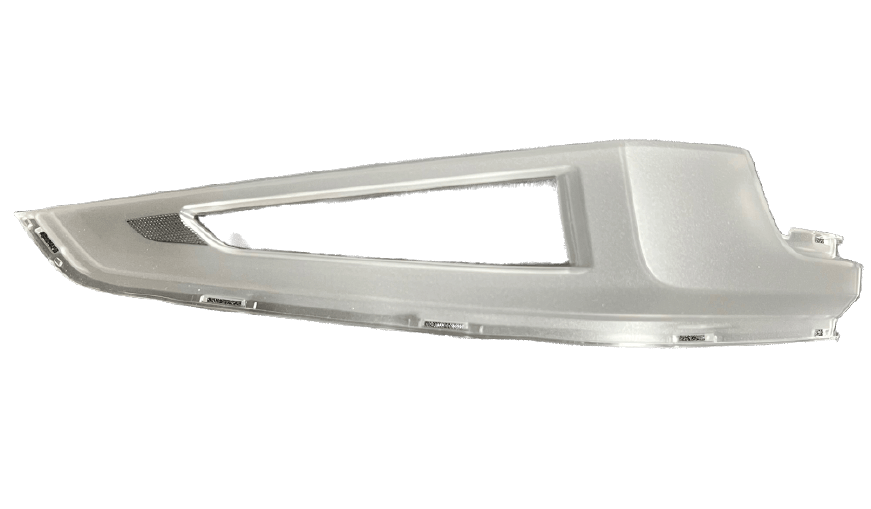

Plastic Lens

Triangle Rubber & Plastics offers custom plastic lens molding for a wide range of automotive applications–from headlights to tail lights and everything in between. Our company has a long history of custom molding exterior components for vehicles, a foundation of experience that sets us apart in the automotive industry. With the equipment to perform single-shot and two-shot molding processes, we take advantage of the technologies best suited for each project.

Bringing Your Molded Plastic Lenses to Life

Molded plastic lenses serve both functional and decorative purposes in vehicles. They are integral parts of the automotive industry and affect first impressions of the finished product. Headlamps and tail lamps are also heavily regulated, and lenses must meet very strict standards to ensure the safety and satisfaction of consumers.

Triangle Rubber & Plastics understands the importance of communication when producing your plastic lenses. We value our customers greatly and dedicate our time to collaborating with you to ensure that each order matches the intended design vision.

Your One Stop Shop for Plastic Lens Molding

If you are looking for a shop that can do it all, you have come to the right place. Triangle Rubber & Plastics has earned a reputation in the automotive industry for being a highly flexible one-stop plastic molding supplier. We can assist you with everything from design to delivery, offering excellent engineering services, high-volume production outputs, and quality plastic lenses, all while meeting quick turnaround times.

Injection Molding for Plastic Lenses

Our two-shot molding technology, sometimes referred to as dual- or multi-shot molding, is ideally suited for molding plastic lenses. Two-shot molding offers flexibility in product design, which allows for more complex part geometries. Moreover, this process easily accommodates various colors, making it the best choice for plastic lens molding.

Lead Times for Plastic Lens Molding

On average, our plastic lens molding RFQ has about a five-day lead time for a return quote as long as the customer provides part data. While providing part data is optional for a quote, with the information, the lead times will likely end up taking longer. Lead times also vary depending on the specific tooling and materials your project requires. Our team can help you with your project and any questions you may have.