Triangle Rubber & Plastics has been in the industry for 75 years, serving a variety of OEM needs with rubber and plastic manufacturing services. Over the years, we’ve made thousands of different parts for our OEM partners, and we’ve seen it all. Customers have come to us with inconsistent quality issues, unfulfilled design promises, or just an inability to deliver. Our goal over the years has been to fix that.

We Don’t Over Promise

We know how complicated the global market can be. So we built our company on a foundation of transparency and consistency. Our customers bring us their designs or their existing tooling, and we tell them exactly what we’re able to do and provide as accurate a quote as possible. Triangle Rubber & Plastics grew into a trusted partner across industries because if we say that we’ll do something, we do it.

We take our customers seriously, maintaining regular updates and communication so that at any time, they know where their parts are at and how their project is progressing. At Triangle Rubber & Plastics, we let our work speak for itself.

Providing Materials that Meet Customer Specifications

One major advantage that Triangle Rubber & Plastics has to offer is our ability to work with any type of plastic available, and formulate rubber compounds to suit each customer’s particular needs. We know how to work with a variety of different thermoplastics, simple to highly engineered, and maintain connections with all major plastic distributors across the country.

In addition, we are a rubber supplier and manufacturer all in one. Customers can bring us their specifications–what function the parts will play, what characteristics and features they need to have, what standards they have to uphold–and we’ll formulate a compound in our laboratory that meets those specifications.

Standardizing for Consistency and Efficiency

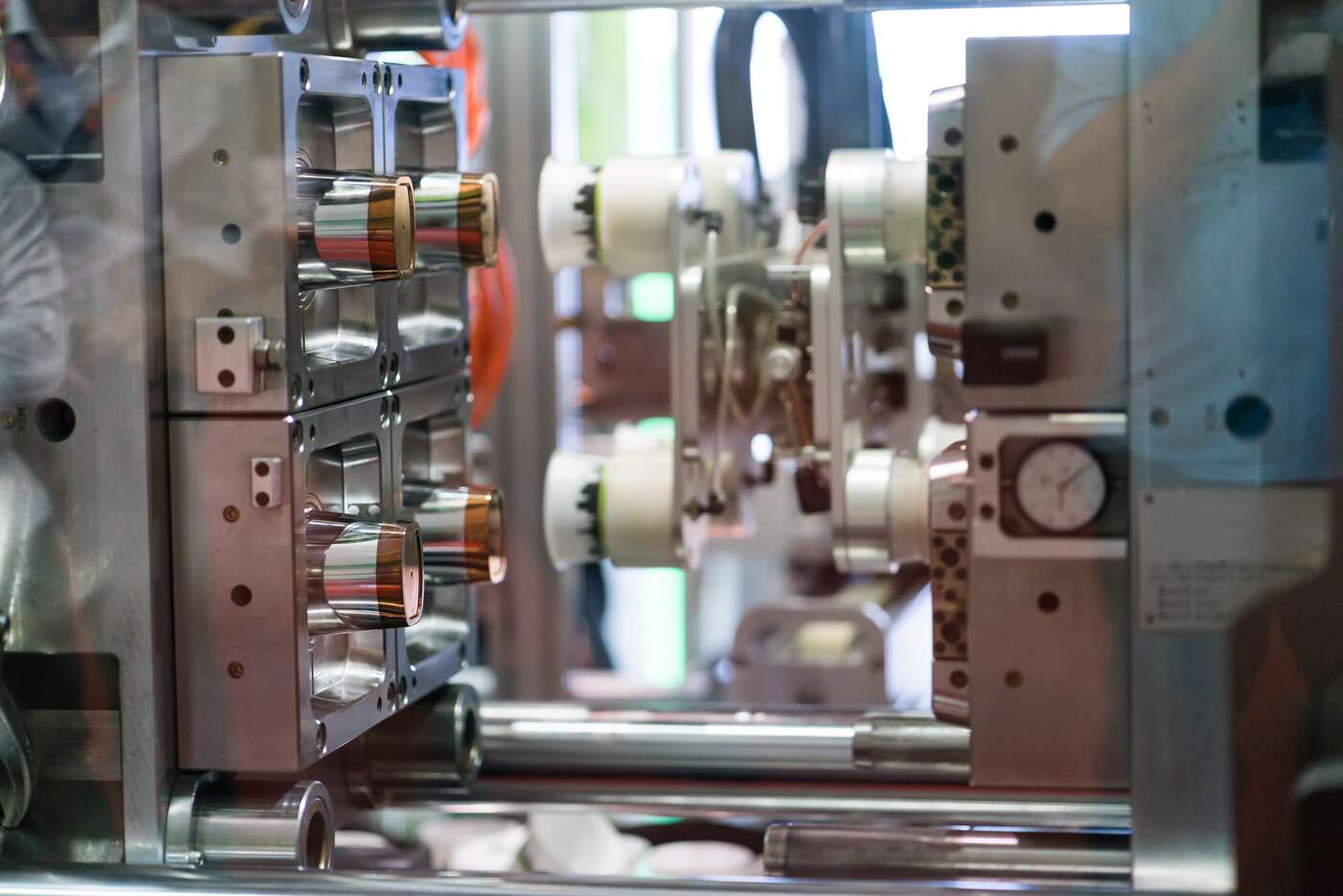

Across our three facilities, we’ve integrated automation that maintains consistent quality across secondary operations so that our operators are free to focus on what they do best. Our automated systems are standardized across the facility to work with any of the parts we make and handle product movement, packaging and labeling, and other processes that might seem simple but still require the consistency that robotics can offer.

The standardization across our molding processes also helps us streamline tooling transfers. If a customer comes to us with existing tooling, Triangle Rubber & Plastics can integrate it into our existing production lines with little to no disruption of everyday operations. We get these customers’ product lines back up and running,

Interested in partnering with us?

Triangle Rubber & Plastics, Inc. is an expert plastic manufacturer, rubber supplier, and rubber component manufacturer with a long history of excellent customer service as our company’s foundation. If you’re interested in what we have to offer, please contact us with your next project.