Value-Added Services and Assembly

Triangle Rubber & Plastics doesn’t just stop at plastic and rubber molding services. Complementing our highly flexible manufacturing capabilities is a wide range of value-added services. We are your one-stop shop for rubber and plastic molding, plastic welding, printing, and various assembly services.

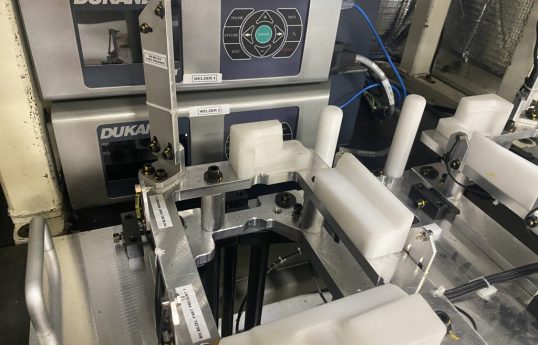

Automation and equipment building are two of our specialties. When our customers need an extra assembly service, we use our engineering expertise to concept, design, and manufacture the equipment necessary for their specific needs. This includes robotic automation technology, welding equipment, and much more.

Pad Printing

One of the value-added services that we provide for our customers is pad printing. Our facilities are equipped with printing technology to successfully transfer images or texts, such as logos, indicators, or other items, onto your plastic or rubber products once we have finished the molding process.

Plastic Welding

In addition to a range of plastic molding services, Triangle Rubber also performs expert sonic and vibratory plastic welding as needed to ensure that our partners receive finished products ready for installation.

Foam Seal Assembly

Another typical assembly operation that Triangle Rubber performs in-house is foam-seal assembly for parts that will be used in applications that require sealing or vibration control.

Part-to-Part Assembly

In addition to simple assemblies and welding, Triangle Rubber & Plastics also offers part-to-part assembly. This means we can mold all rubber or plastic components required for a particular product and then integrate these parts into the assembly or subassembly, all in-house.

Fastener Assembly and Screw Inserts

If your parts will eventually require fasteners or screw inserts, then we can take care of that in-house for you! We have plenty of experience building automated fastening technologies to quickly and efficiently incorporate the rubber or plastic parts we mold into final assemblies. This helps eliminate further secondary processing and assembling that our customers typically would have to do independently. They’ll receive a fully assembled product from us ready for installation as soon as it arrives at their facility.